Ningbo Force Auto Parts Co., Ltd.

- joe@forcerigging.com

- +86-18650363763

Ningbo Force Auto Parts Co., Ltd.

By: Joe , Lead Engineer with 10 Years of Rigging Design Experience, Force Rigging.

In the high-stakes environment of logistics, securing a load is more than a simple chore—it's a critical mission. Force Rigging, a trusted leader in cutting-edge rigging solutions, proudly unveils its definitive guide to mastering ratchet tie-down straps in a mere five minutes. Grounded in decades of technical expertise and relentless testing, this detailed, step-by-step tutorial equips procurement managers and logistics teams to secure cargo with professional precision—boosting efficiency, minimizing costs, and guaranteeing paramount safety. Here is the proven methodology, supported by real-world applications, technical specifications, and tools certified to the highest global standards.

Content

An unsecured load can trigger catastrophic results: damaged inventory, costly delivery delays, or serious safety incidents. Consider the documented instance of a Midwest trucking company in 2023 that incurred $50,000 in equipment loss following a failure to properly secure a flatbed load (source: Transport Topics). When deployed correctly, ratchet straps are the ultimate safeguard against such liabilities. “We frequently receive queries from clients about the markings on our straps,” notes Joe, Force Rigging’s Lead Engineer with 10 years of rigging design experience. “Our response is simple: they signify strength and reliability—and here is our time-tested method.”

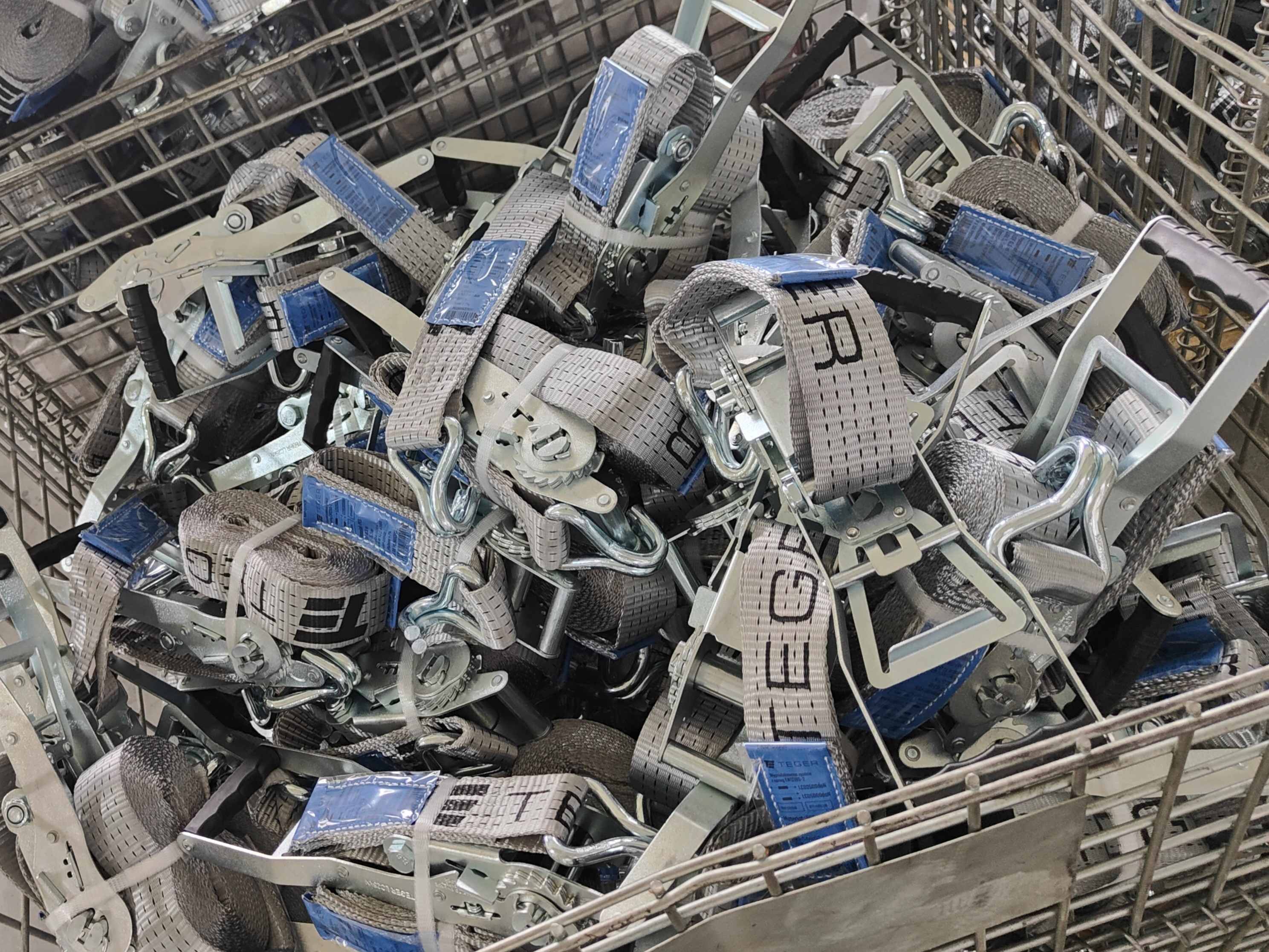

Force Rigging's premium ratchet straps, fully compliant with EN 12195-2 and CE standards, feature 50mm-wide webbing engineered for a 5-ton breaking strength. This material is meticulously crafted to be UV-resistant and exceptionally durable, forming the backbone of truly efficient cargo control.

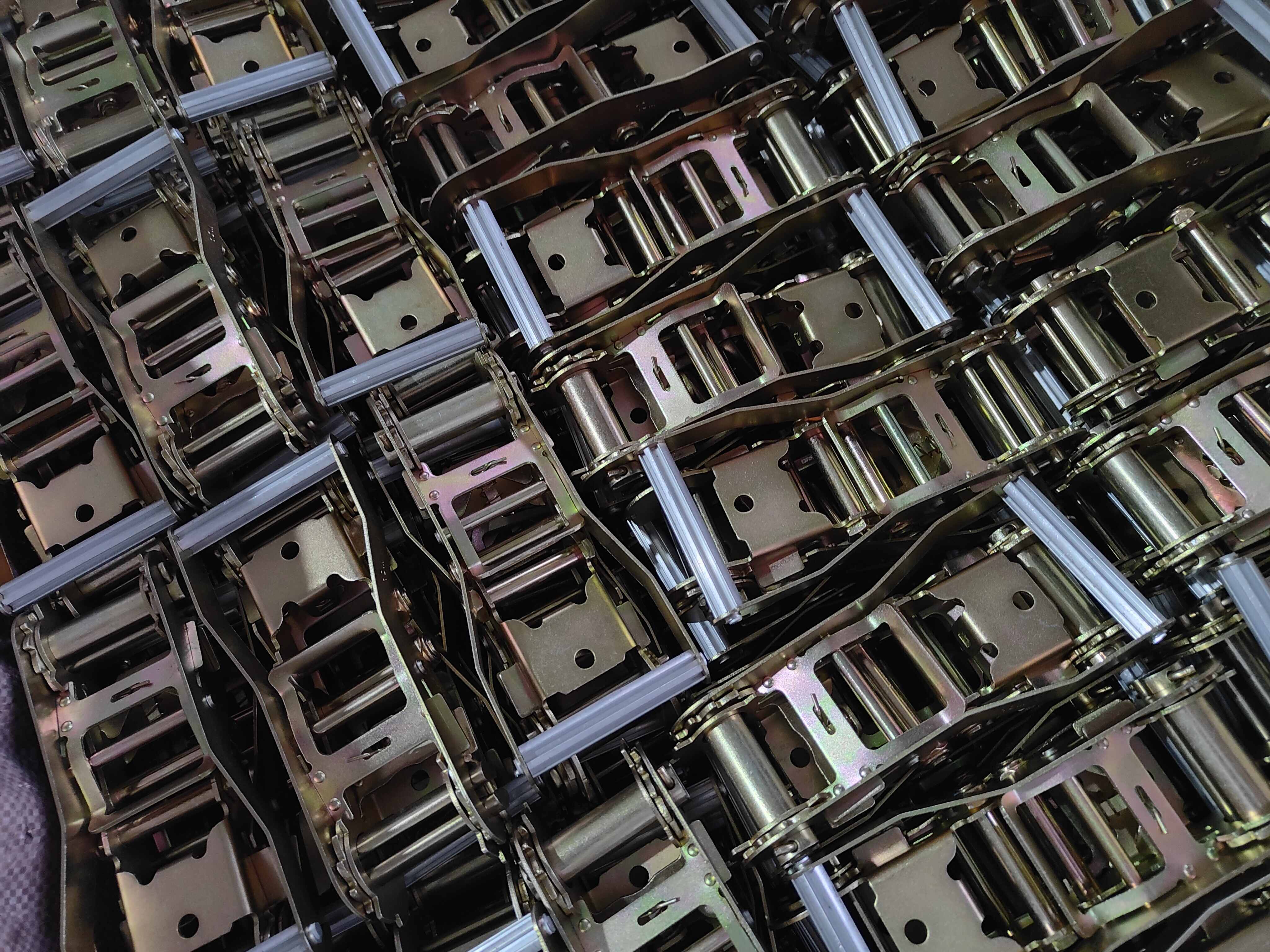

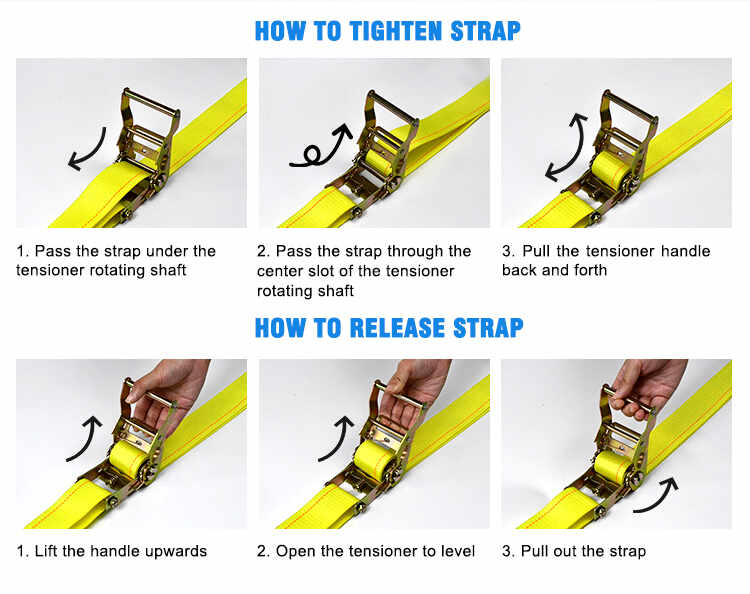

1.Engage Full Open Position – Depress the release catch to fully extend the mandrel (the 2-inch steel spindle, featuring a tensile strength of 800 MPa).

2.Guide the Webbing – Smoothly thread the 50mm polyester webbing (rated for an abrasion resistance of 7,000 cycles) through the central slot.

3.Secure the Anchor – Pull the strap back, creating a loop over the mandrel to establish a secure attachment.

4.Achieve Initial Snugness – Adjust the strap, leaving only a minor amount of slack; the final tensioning process is next.

Real-World Example: A Force Rigging customer in Shanghai flawlessly secured 20 tons of steel pipes for a demanding 500-mile transit using this precise method—experiencing zero load shifts or product damage.

1.Connect S-Hooks – Firmly attach the forged steel end hooks (rated for a proof load of 2.5 tons) to the designated anchor points on your vehicle.

2.Eliminate Excess Slack – Pull the strap taut until all initial looseness is removed.

3.Crank to Firmness – Operate the ratchet (which boasts a mechanical gear ratio of 4:1) until the load is immovably firm—our internal lab testing demonstrates its capability to hold up to 5 tons without slippage.

4.Final Lock-Down – Close the handle completely to engage the integrated auto-locking mechanism.

Testing in Action: Within our controlled Ningbo lab environment, we subjected our straps to an intense 10,000 tension cycles. The results confirmed zero material degradation, consistently meeting rigorous ISO 9001 quality benchmarks.

1.Disengage Lock – Pull the ergonomic release tab (which requires an actuation force of only 10N).

2.Smooth Extraction – Slide the strap free without difficulty, facilitated by the non-jamming internal components.

3.Compact Storage Prep – Neatly fold the strap to prepare it for subsequent use.

Field Test Validation: A logistics team operating in Guangzhou successfully unloaded a 15-ton shipment in under 10 minutes utilizing this systematic release technique—a clear demonstration of peak operational efficiency.

1.Coil Systematically – Tidy the 10-meter strap to prevent frustrating knots and tangles.

2.Intelligent Placement – Store the straps in a dry, shaded location; our webbing is certified to resist 2,000 hours of UV exposure (in accordance with GS standards).

3.Pre-Use Inspection – Conduct a visual check for any signs of wear and tear to ensure continued, reliable performance.

Pro Tip for Preservation: Utilize a dedicated wall rack or employ Force Rigging’s protective gear bag—clients consistently report a 30% increase in the typical strap service life.

Our straps are engineered to be more than mere tools—they are robust load security solutions. Proven in demanding, real-world scenarios (such as a 2024 trial securing wind turbine blades across Xinjiang province), they consistently deliver on:

Efficiency: Rapid threading drastically minimizes frustrating downtime.

Durability: The 5-ton capacity ensures resilience against the most severe environmental conditions.

Safety: Certified to EN 12195-2, guaranteeing the protection of both your personnel and your valuable cargo.

"Force Rigging's sustained legacy is fundamentally built upon continuous innovation," asserts Joe. "Our diverse clientele—including a German automotive supplier that secures 100 pallets weekly—trusts us implicitly for this level of precision.

Certified Quality Assurance: We are a proud member of the WTDA, holding impeccable ISO 9001 and CE credentials.

Transparent Technical Specs: Detailed product sheets and engineering data are available upon request at joe@forcerigging.com.

Globally Trusted: Our solutions are the preferred choice of logistics firms operating in over 20 countries worldwide.

1. What is the significance of the lines printed on the ratchet straps?

The printed lines serve as a clear visual indicator of the strap's breaking strength—our products are marked for 5 tons. “It functions as an instantaneous visual safety cue,” explains Joe Zhang.

2. How much tension should I apply to the strap?

Tighten the strap until the load is held securely firm, but take care not to excessively strain the cargo—over-tightening risks physical damage. Our ratchets' 4:1 gear ratio is designed to provide highly controlled tensioning.

3. Are these straps capable of withstanding extreme weather conditions?

Absolutely. Our advanced UV-resistant webbing is capable of enduring 2,000 hours of direct sunlight, and lab tests confirm consistent performance across a wide temperature range, from −40∘C to 80∘C.

4. What is the recommended replacement frequency for my ratchet straps?

Perform a meticulous inspection before every single use. Replace the strap immediately if you observe any fraying, cuts, or significant wear—our straps typically provide 2-3 years of service life with diligent maintenance.

5. Are Force Rigging straps compliant with all relevant global regulations?

Unquestionably. They meet the stringent requirements of EN 12195-2, CE, and GS standards, ensuring full compliance for legal and safe deployment anywhere in the world.