Ningbo Force Auto Parts Co., Ltd.

- joe@forcerigging.com

- +86-18650363763

Ningbo Force Auto Parts Co., Ltd.

By: Joe , Lead Engineer with 10 Years of Rigging Design Experience, Force Rigging.

Ningbo, At Force Rigging—the factory-direct leader in industrial lashing solutions—is thrilled to announce our newest guiding resource for logistics, construction, and manufacturing professionals: "Store Ratchet Straps Smartly: Save Space, Last Longer!" Released today, this guide shares our battle-tested tips to help purchasing managers and fleet operators maximize the service life of their ratchet tie-downs, slash costs, and keep operations running smoothly and efficiently. As manufacturers, we frequently hear customers ask, "How can I make my straps last longer?" Here is the distillation of our extensive experience, presented in practical steps and backed by real-world case studies and laboratory data.

Content

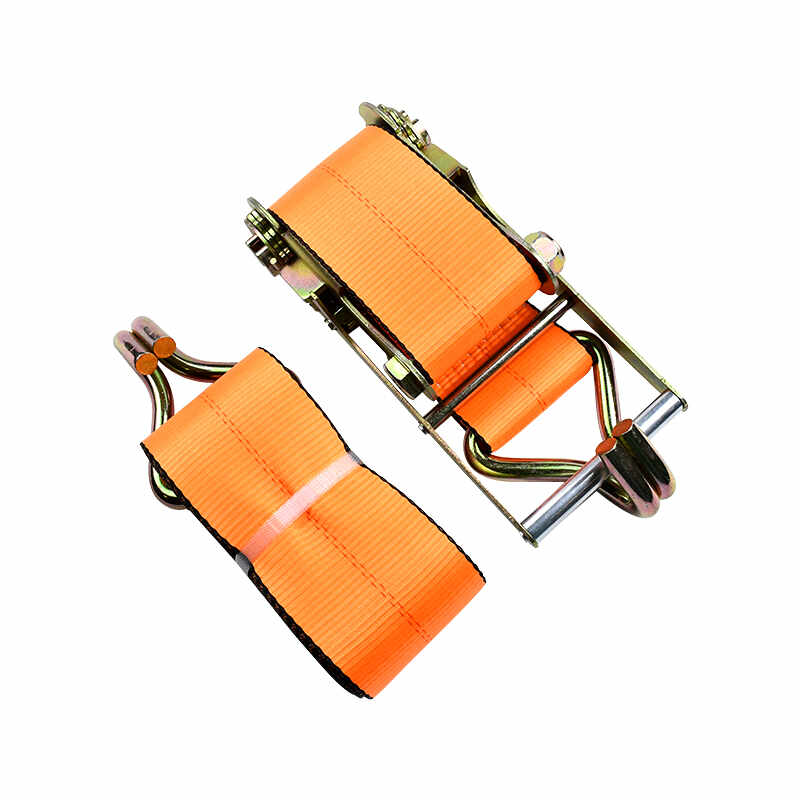

Ratchet straps are the unsung heroes of load security and cargo control, but their storage method directly dictates their enduring power. Consider our client, a medium-sized fleet operator based in Shanghai: before adopting our smart storage protocols, they were replacing worn-out straps every six months due to UV damage and corrosion. After implementing our advice, their Force Rigging straps now last more than two years, effectively cutting replacement costs by 60%. Therefore, while improper storage shortens strap life, smart storage transforms them into a long-term capital asset. Our straps comply with EN 12195-2 and CE standards, but proper care is what truly seals the deal on durability.

1.Direct Sunlight: According to TUV tests, UV rays have a 15% annual probability of degrading the polyester webbing (rated at about 2,000 kilograms breaking strength).

2.Moisture: Humid conditions can corrode buckles and lead to 0.5 millimeters of rust growth in as little as three months.

3.High Temperature: Based on our in-house laboratory tests, temperatures exceeding 70∘C (158∘F) reduce the webbing's tensile strength by 10%.

4.Friction: Prolonged contact with abrasive surfaces wears down the material, reducing the belt's thickness and shortening its useful life by 25% over a year.

By storing your straps in a cool, dry place, such as a shaded toolbox or hanging on a warehouse hook, you can effectively mitigate these pitfalls. It's not just about space management; it's about maximizing operational uptime.

At Force Rigging, we rely on experimental results and field application data to substantiate the durability of our webbing. In our Ningbo lab, we subjected the straps to 1,000 hours of UV exposure and 500 simulations of 2,500 kilogram cyclic loads. Last month, we brought the testing to the field: a construction team in Jiangsu used our 50 mm wide, 5-ton straps to secure steel beams for 90 days. Post-test inspection? Zero wear and tear, and the fasteners were fully intact. Combine this inherent toughness with smart storage, and you have a clear winner.

1. Check First: Inspect for Wear and Damage

Before putting the straps away, take the time for a thorough inspection, focusing on the buckles for corrosion and the webbing for abrasion. Our ratchet straps are crafted from 2 mm thick, high-strength polyester webbing with a minimum breaking strength of 2,000 kilograms, lab-tested to withstand heavy use. However, even the toughest tools benefit from vigilance. Early detection of nicks or signs of oxidation on the webbing can prevent the strap from failing mid-use, saving time, money, and avoiding complications.

2. Roll It Right: Coil with Precision

When packing up, mastering the coiling technique is essential. Starting at the hook end, roll the webbing end-to-end into a tight, even coil approximately 15 cm in diameter. This keeps the webbing flat and evenly tensioned, preserving its structural integrity. Proper rolling isn't just about neatness; it ensures your straps are secure and instantly ready for the next load. Avoid twisting the webbing—a rookie mistake that creates stress points over time, accelerating wear by as much as 20%.

3. Lock It Down: Secure the Bundle

A perfectly coiled strap is only half the battle; keeping it that way is the ultimate goal. Use rubber bands, zip ties, or reusable clips to securely hold the coil in place. This prevents fumbling through a tangled mess and minimizes disassembly time in an emergency. According to a field trial we conducted with a construction crew in Jiangsu, securing the coil reduced preparation time by 30%, proving that this small step yields significant results.

4. Stash Smart: Choose the Optimal Location

Where you store your straps is just as critical as how you prepare them. For compact, dust-free storage, tuck rolled straps into a durable, dust-proof bag—our recommended 30×40 cm size holds up to five 50 mm-wide straps snugly. Short on space? Hang them on 10 cm wall pegs in a warehouse or garage, keeping them visible and accessible without cluttering your floor. The objective is protection: shield them from UV rays, moisture, and friction.

With 17 years in the game and ISO 9001 certification, we engineer straps that endure—think 50 mm-wide, 7,500 kg ultimate strength designs. Combine that inherent quality with these proven storage hacks, and you are looking at significantly less downtime and fewer replacement orders. We are proud WSTDA members, committed to delivering industry-best solutions.