Ningbo Force Auto Parts Co., Ltd.

- joe@forcerigging.com

- +86-18650363763

Ningbo Force Auto Parts Co., Ltd.

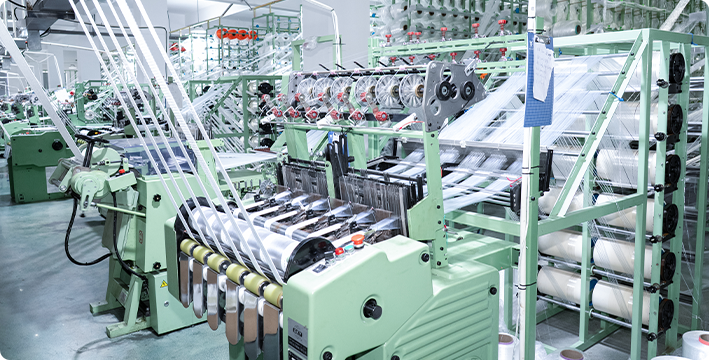

Factory Area

Professional Employees

Manufacturing Experience

Punching Machine

Accessory Assembly

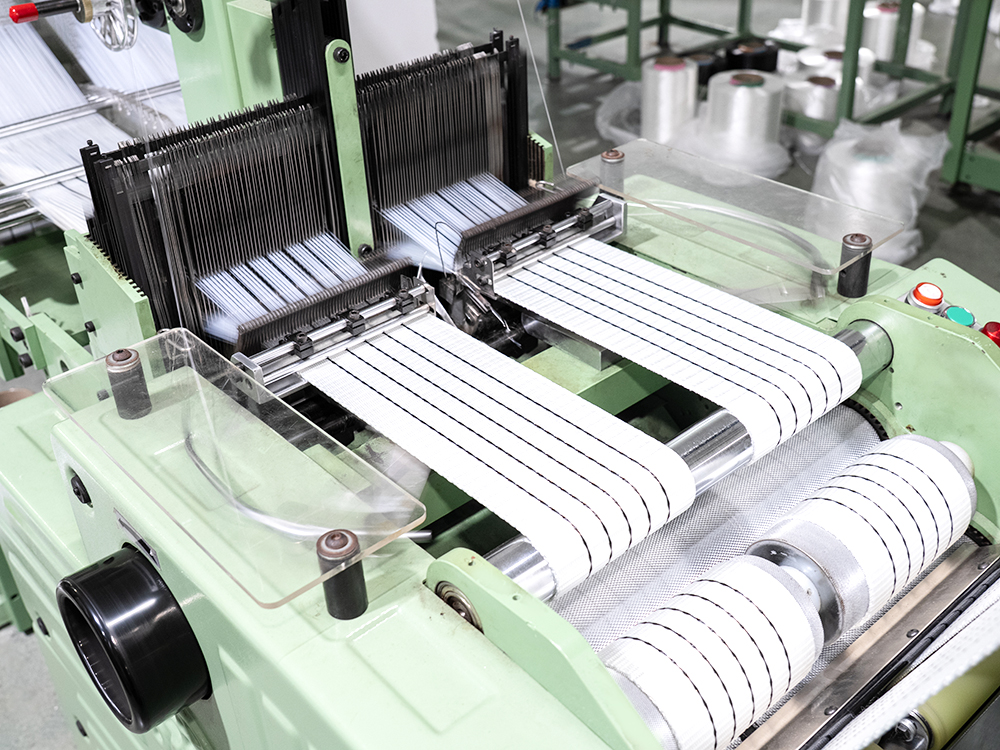

Weaving Tape

Dyeing

Printing

Cutting Tape

Sewing

Production

Testing

Packing

Ningbo Force Auto Parts Co., Ltd. operates a high-standard factory designed for quality and efficiency. Our facility integrates sound infrastructure with complete functional zones, ensuring an optimal environment for large-scale, high-quality production.

Everything Starts with an Idea !